The purpose of this project was to design, model, and integrate a novel custom force measurement system within a previously-designed aeroshell. The proposed solution seeks to answer the question, “What would wind tunnel models look like if they were not traditionally manufactured?” If adopted, the final design could improve the speed with which proof of concept designs can be tested, increase the fidelity of data available during wind tunnel analysis, and reduce prototyping costs. The outer-mold line (OML) that houses the force measurement system is based on the NASA Viking 2 Lander aeroshell, which allows for the final design to be experimentally tested against previous wind tunnel data. Using computational methods like finite-element analysis (FEA) and computer-aided design (CAD), as well as analytical tools like MATLAB, several rounds of design iterations were completed. Over the course of these iterations, model printability was refined, while progress was made concerning factors of safety for stress and desired gauge outputs for strain. Different materials and methods for reduction of temperature effects were explored and compared, as were different strategies for ensuring model printability.

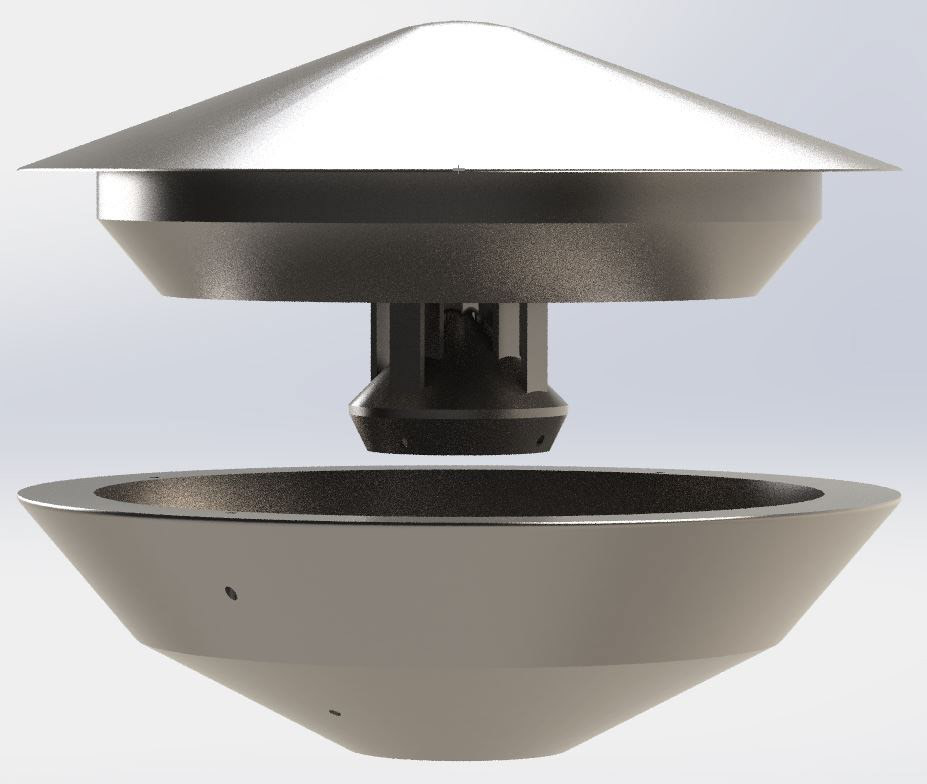

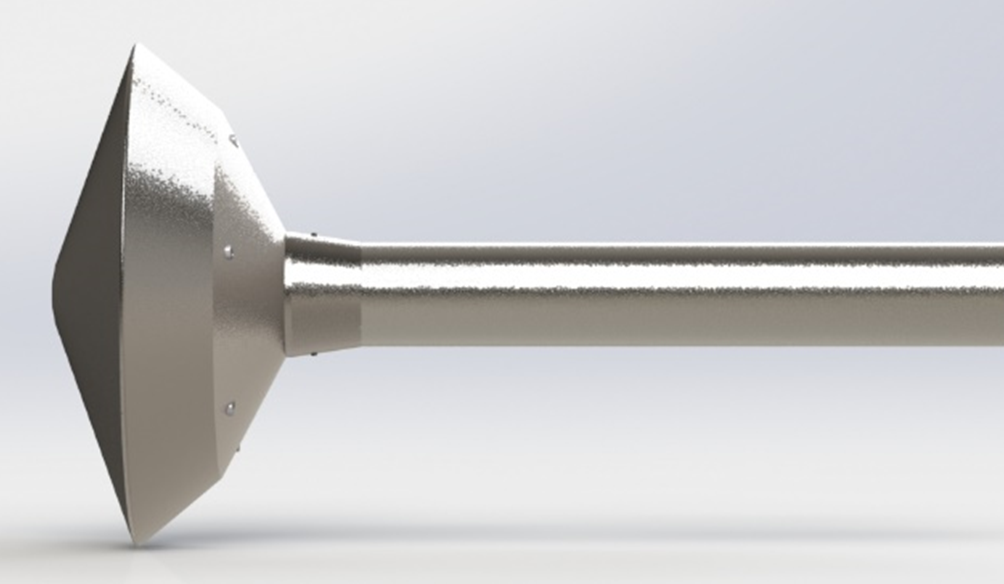

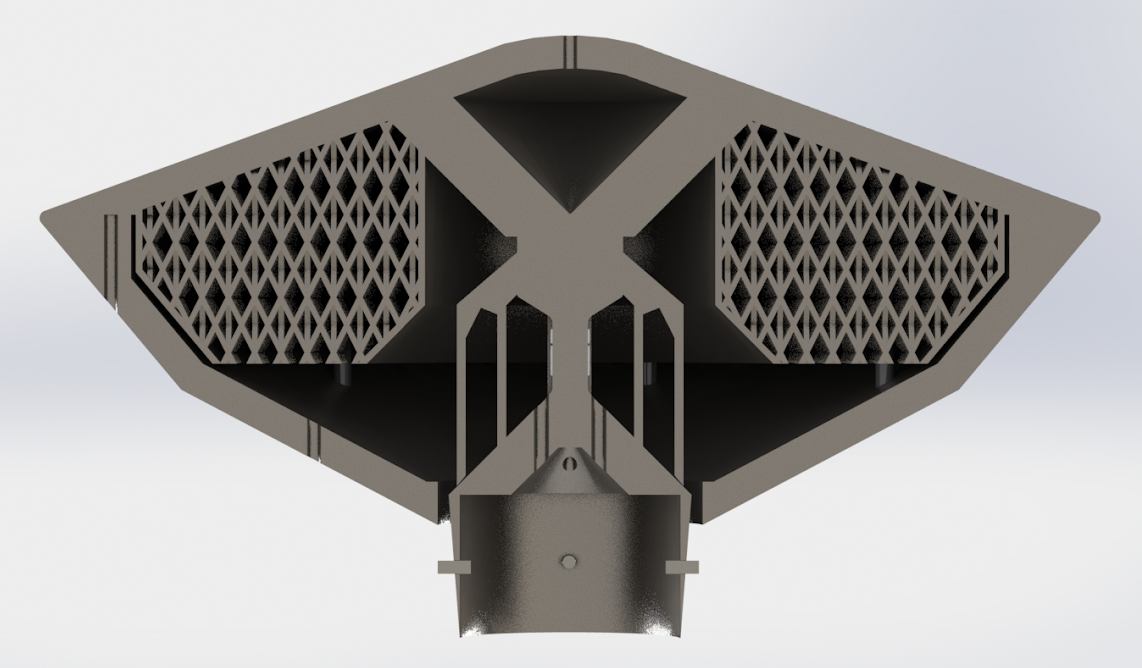

The final design iteration includes a single model with conventional pressure instrumentation, a cooling system, and an integrated custom force measurement system. The integrated custom force measurement system utilizes three Wheatstone bridge circuits composed of twelve strain gauges, which serve to record global forces and moments on the model. Using direct metal laser sintering methods, the model can successfully be printed in two main parts (the forebody and the afterbody) due to 45° chamfers and other design features. The final cooling system design keeps all strain gauges within their 180° F temperature limit, and the model itself meets NASA’s factors of safety to withstand the tunnel’s most extreme load case. With the final design iteration complete, NASA may print the model on-location and conduct experimental tests in their Mach 6 and Mach 10 wind tunnels. If the results are promising, this technology could become the industry standard for wind tunnel model rapid prototyping.

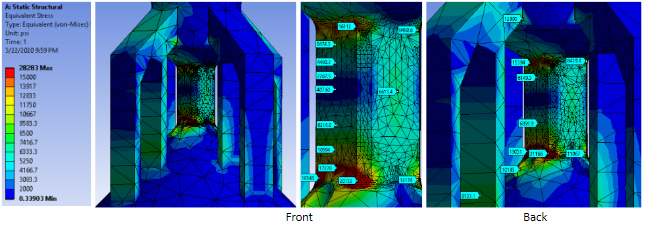

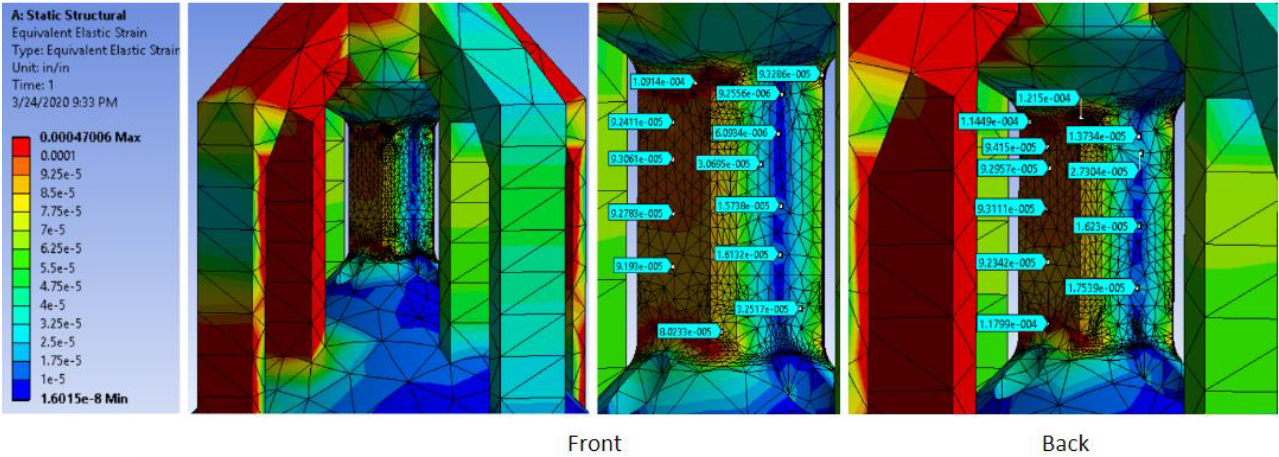

To ensure factors of safety were met, an ANSYS Workbench simulation was completed using the most extreme load cases as the applied boundary conditions. Through the simulation, equivalent von Mises stress values on the force measurement system were found, verifying the required factors of safety. Expected strain values when applying the maximum non-unstart loads in the Mach 6 tunnel were also determined using a similar method.

To verify the effectiveness of the chosen cooling mechanism design, ANSYS Workbench was once again used to verify the calculated wall temperatures expected to result from the thermal conditions of the wind tunnel. It was also determined through this simulation that the temperature of the strain gauge measurement system is at an acceptable level even when exceeding worst case testing scenarios.